Whatâs trending in garment decoration

September 28, 2020

What's trending in garment decorating? ScreenPrinting Magazine recently published an article by Kieth Stevens about the trends that are in the market today:

As businesses are steadily reopening, we at International Coatings Company have seen a surge in demand of specialty ink requests from garment decorators, almost on a daily basis. Many printers are printing masks and other PPE supplies, but the regular garment business has started to grow, as well. The most popular decorating trends seem to be reflective and foil, but in general, all things shiny seem to be catching decorators’ attention.

Why should you consider following this trend? First, your customers are probably asking for it. Second, you can differentiate yourself from other shops by offering on-trend, in-demand looks. And third, it’s good for your bottom line, as specialty printing can generally be priced higher than regular prints, with not much additional effort or costs if done correctly.

Here’s a brief rundown of how your shop can catch this current trend.

Reflective inks

Reflective prints give designs visibility during low light conditions when hit by a bright light. Typically, reflective inks contain microscopic glass beads that are coated with a reflective material, thus creating a retro-reflectivity when a beam of light hits the print. Think about using reflective ink on jogging or biking outfits, the back of a jacket, or the side of a legging where a pop of reflective color might be unexpected or even practical.

There is a variety of different reflective inks on the market. Some of our reflective inks can be printed using higher mesh counts for great detail. Check with your ink manufacturer for proper mesh counts and curing temperatures.

Foil adhesives

Foil is another hot trend. It can make your designs stand out and get noticed. With an array of foils available in the market, you can create a shiny design in an almost endless color pattern. Foil can be added on parts of a design or for an all-over foiled look. Pro tip: try adding a color pigment, to match the color of the foil, to your adhesive. This trick will help you hide any tiny imperfections that may occur during the foil transfer.

A distressed foil application method, whereby the foil is rubbed over the design using a cloth or rag after the adhesive is flashed (while still on the platen) is another cool way of adding foil effects. This method does not require a heat transfer press, and can also be applied over certain dimensional inks, such as specialty gel gloss inks. Most foil adhesives are printed through a 74–110 mesh count depending on the design.

Glitter inks

Glitter ink is a nice addition to your repertoire. It adds the perfect amount of “bling,” even to simple designs. Glitter is versatile and easy to print. It can be used for fashion designs, logos, children’s wear, and much more. Be sure to print glitter inks through coarser mesh counts to allow for the glitter flakes to pass through and get a good ink deposit. Typically, a 24 mesh count is recommended for the best results. Here’s a trick to hide the low-mesh marks that may show on the final print: try adding additional coatings of emulsion to the bottom of your stencil. This will raise your ink deposit and allow ink to flow underneath the mesh to make the print smoother and more appealing.

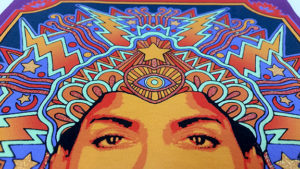

Shimmer inks

Similar to glitter inks, shimmer inks are versatile and add interest and a shine to any print. Shimmer inks use a finer metallic particle and can be printed through higher mesh counts (86 to 120). One of our most popular shimmers is crystalina. The flakes are translucent, with a coating that reflects light and shimmers in multiple colors. The ink can be used on its own or printed over other colors. The ink allows the colors and design to show through, but adds an extra pop to the design.

Keep in mind that any shiny or reflective ink requires longer cure time because they not only reflect light but also heat. Adjust your dryer to achieve full cure temperatures. Usually, a slower belt speed will do the trick. Always test before going into production.