What’s the Difference between Optilux 505 and 507?

November 26, 2013

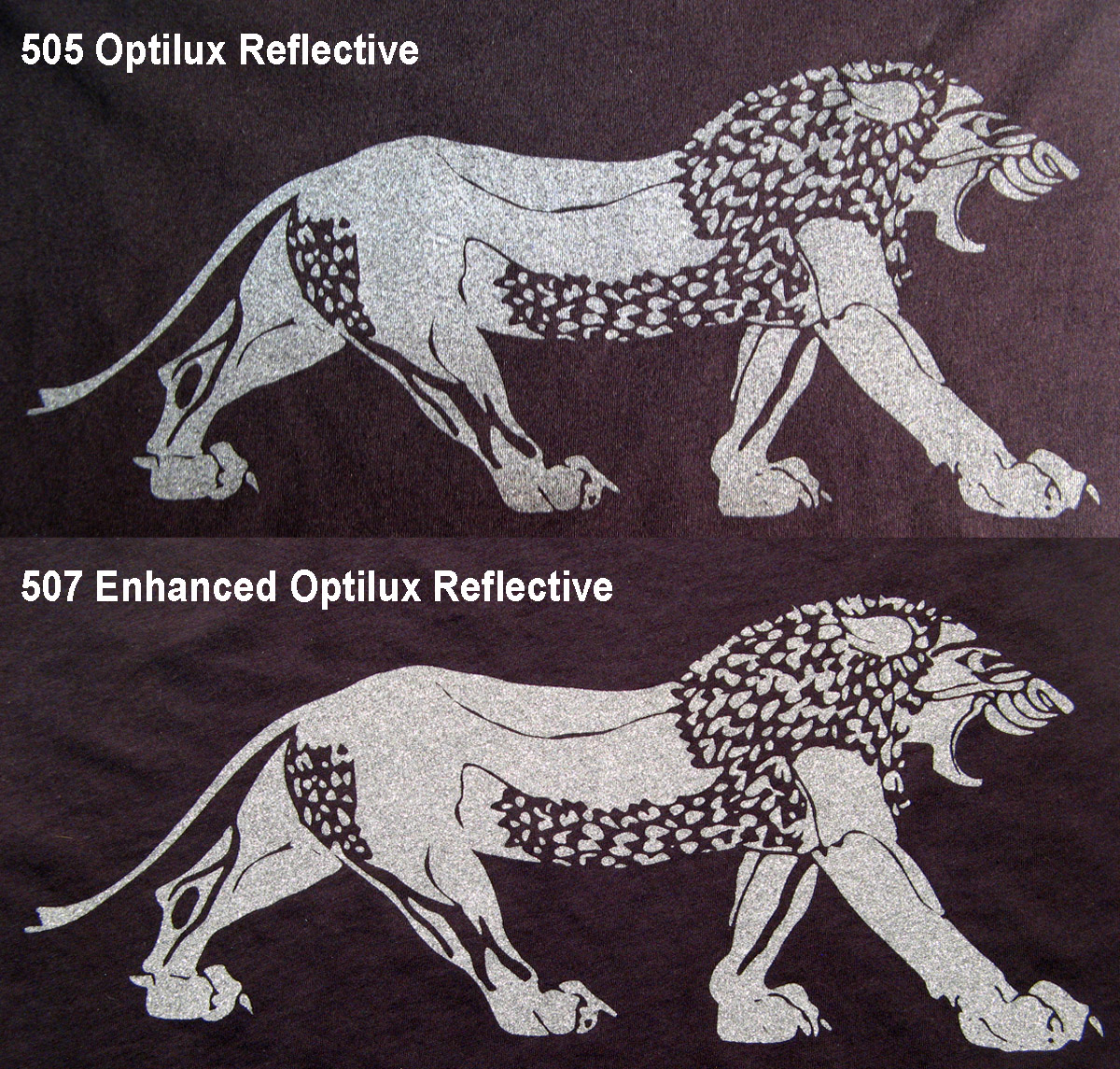

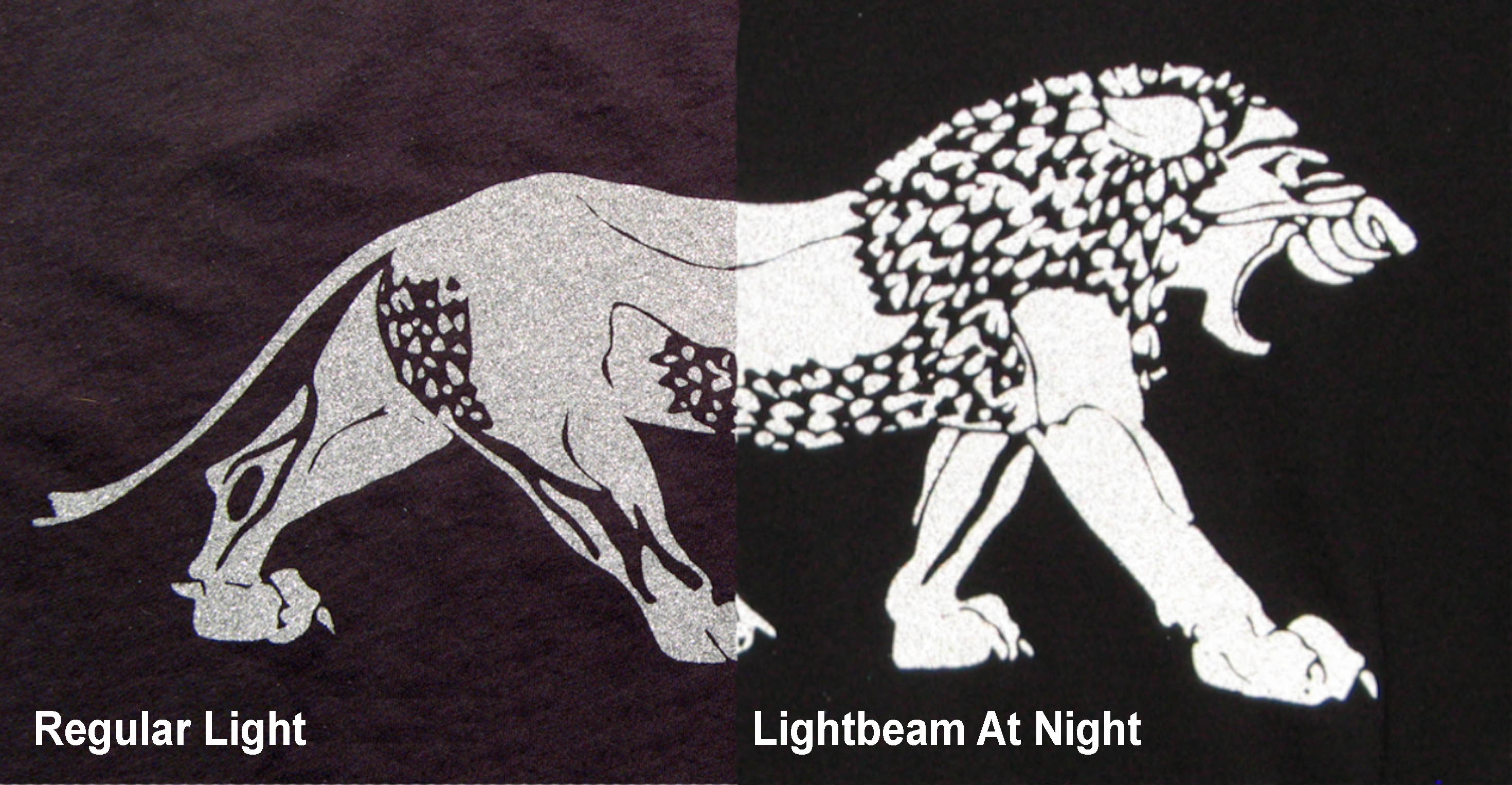

Recently, we have received a number of inquiries on the difference between the Optilux 505 and the 507. The primary difference between the two products is that Optilux 507 contains sliver shimmer flakes which make it appear more opaque than the Optilux 505 when viewed in daylight. For those that are primarily printing a one color print, or need more opacity, the use of the Optilux 507 Enhanced Reflective is recommended. The Optilux 505 is for use on designs where you may want the reflective ink to be a part of the design that is somewhat hidden until hit with light.

The Optilux 507 was formulated to give better opacity and a different look than Optilux 505 when doing, in particular, one color prints. The Optilux 507 has enhanced opacity because it also contains a very small metallic flake which helps with opacity. Properly printed and cured, Optilux 507 will be more opaque and will appear more like a sliver shimmer type ink under normal lighting conditions, but will reflect very well when exposed to a focused beam of light, such as that from a flashlight or car headlights.

The Optilux 507 and 505 is an easy to print, two-part, retro-reflective ink that contains light-reflecting microspheres. When a garment printed with the Optilux ink it is exposed to a focused beam of light, such as that from a flashlight or an automobile headlight, it reflects or returns light back at the light source.

Recently, we have received a number of inquiries on the difference between the Optilux 505 and the 507. The primary difference between the two products is that Optilux 507 contains sliver shimmer flakes which make it appear more opaque than the Optilux 505 when viewed in daylight. For those that are primarily printing a one color print, or need more opacity, the use of the Optilux 507 Enhanced Reflective is recommended. The Optilux 505 is for use on designs where you may want the reflective ink to be a part of the design that is somewhat hidden until hit with light.

The Optilux 507 was formulated to give better opacity and a different look than Optilux 505 when doing, in particular, one color prints. The Optilux 507 has enhanced opacity because it also contains a very small metallic flake which helps with opacity. Properly printed and cured, Optilux 507 will be more opaque and will appear more like a sliver shimmer type ink under normal lighting conditions, but will reflect very well when exposed to a focused beam of light, such as that from a flashlight or car headlights.

The Optilux 507 and 505 is an easy to print, two-part, retro-reflective ink that contains light-reflecting microspheres. When a garment printed with the Optilux ink it is exposed to a focused beam of light, such as that from a flashlight or an automobile headlight, it reflects or returns light back at the light source.

The printing of both products is very similar and it is important that the printing procedures given in this article are followed in order obtain the best results. Note that both of the Optilux products are recommended for use on open weaved fabrics such as 100% cotton or poly/cotton blends.

Another important fact about both products is, in order to obtain the best results when using the Optilux direct print products that the inks always be thoroughly stirred prior to each use. The reason for this is that the reflective glass beads can settle in the container when the inks are stored for any length of time and if not stirred before each use, the reflective bead distribution will not be even and this can limit reflectivity.

Lastly it is very important to NOT modify these inks with any thickeners or thinners. You also do not want to use any under base when printing the Optilux products as the under base will not allow the ink to sink into the fabric and you will lose reflectivity or the ink may not reflect at all. In the same respect, you do not want to lay down so much ink that the reflective beads become covered by excess ink that cannot soak into the fabric.

The printing procedures for the Optilux 507 are much the same as with the Optilux 505 but a more open mesh should be used. The recommended screen mesh when printing Optilux 507 is a 110 t/in (43 t/cm) monofilament mesh. The reason for using a little more open mesh with this product is to obtain more opacity and to allow the ink to pass through the screen mesh properly because of the small metallic flakes that are in this ink.

For more on our Optilux™ Reflectives, go to https://iccink.com/optilux/index.htm. To access the product bulletin for Optilux™ 505 or 507, please go to our product bulletins page: https://iccink.com/screenprint/productbulletins.htm.

The printing of both products is very similar and it is important that the printing procedures given in this article are followed in order obtain the best results. Note that both of the Optilux products are recommended for use on open weaved fabrics such as 100% cotton or poly/cotton blends.

Another important fact about both products is, in order to obtain the best results when using the Optilux direct print products that the inks always be thoroughly stirred prior to each use. The reason for this is that the reflective glass beads can settle in the container when the inks are stored for any length of time and if not stirred before each use, the reflective bead distribution will not be even and this can limit reflectivity.

Lastly it is very important to NOT modify these inks with any thickeners or thinners. You also do not want to use any under base when printing the Optilux products as the under base will not allow the ink to sink into the fabric and you will lose reflectivity or the ink may not reflect at all. In the same respect, you do not want to lay down so much ink that the reflective beads become covered by excess ink that cannot soak into the fabric.

The printing procedures for the Optilux 507 are much the same as with the Optilux 505 but a more open mesh should be used. The recommended screen mesh when printing Optilux 507 is a 110 t/in (43 t/cm) monofilament mesh. The reason for using a little more open mesh with this product is to obtain more opacity and to allow the ink to pass through the screen mesh properly because of the small metallic flakes that are in this ink.

For more on our Optilux™ Reflectives, go to https://iccink.com/optilux/index.htm. To access the product bulletin for Optilux™ 505 or 507, please go to our product bulletins page: https://iccink.com/screenprint/productbulletins.htm.