What type of platen adhesive should I use for screen printing garments?

April 23, 2014

Most printers have several different types of platen adhesive in stock for various needs. To determine which to use, consider the following:

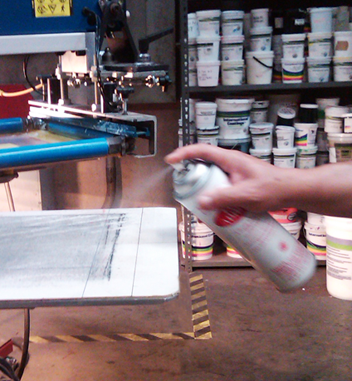

A spray or mist adhesive is the most popular and is great for printing several quick samples or a short production run. There are also heat-resistant formulas available for use with a flash cure. However, there is a lot of overspray which releases chemicals into the air, contributes to waste, and may get into other parts of your print setup.

When printing heavier garments, use the web-type spray adhesive. This type is thicker and may puff up to create more surface for fleece or other fabrics with more loft to adhere to.

Another great adhesive is the economical water-base adhesive that can be applied with a brush, squeegee, or spatula. Simply use a sponge to reactivate the adhesive and clean up can be done with water or alcohol.

For larger-volume print jobs, liquid bulk adhesive is great. These can be rolled on, brushed on, or sprayed on using a compressed air sprayer. Several manufacturers sell corresponding sprayers for their bulk adhesive products.

Finally, there is roll or sheet adhesive. These products are similar to double-sided tape and cover the platen evenly if applied correctly. However, the adhesive often does not last long and the tape should be replaced on a regular basis to avoid residue left on the platen.

Kieth Stevens is the Western regional sales manager for International Coatings. He has been teaching screen printing for more than 10 years and is a regular contributor to International Coatings’ blogs.

International Coatings manufactures a complete line of phthalate-compliant screen printing inks, including a wide variety of whites, specialty inks, special effects inks, color matching systems, additives and reducers. For more information on our products, please visit our website at www.iccink.com.

Most printers have several different types of platen adhesive in stock for various needs. To determine which to use, consider the following:

A spray or mist adhesive is the most popular and is great for printing several quick samples or a short production run. There are also heat-resistant formulas available for use with a flash cure. However, there is a lot of overspray which releases chemicals into the air, contributes to waste, and may get into other parts of your print setup.

When printing heavier garments, use the web-type spray adhesive. This type is thicker and may puff up to create more surface for fleece or other fabrics with more loft to adhere to.

Another great adhesive is the economical water-base adhesive that can be applied with a brush, squeegee, or spatula. Simply use a sponge to reactivate the adhesive and clean up can be done with water or alcohol.

For larger-volume print jobs, liquid bulk adhesive is great. These can be rolled on, brushed on, or sprayed on using a compressed air sprayer. Several manufacturers sell corresponding sprayers for their bulk adhesive products.

Finally, there is roll or sheet adhesive. These products are similar to double-sided tape and cover the platen evenly if applied correctly. However, the adhesive often does not last long and the tape should be replaced on a regular basis to avoid residue left on the platen.

Kieth Stevens is the Western regional sales manager for International Coatings. He has been teaching screen printing for more than 10 years and is a regular contributor to International Coatings’ blogs.

International Coatings manufactures a complete line of phthalate-compliant screen printing inks, including a wide variety of whites, specialty inks, special effects inks, color matching systems, additives and reducers. For more information on our products, please visit our website at www.iccink.com.