Using The Process Color Selector Wheel

May 29, 2015

Here's a quick tip from John Hatcher, recently published in Impressions: We recently found some old promo and marketing materials in our warehouse, and amongst the give-away items, we found a box of Process Color Selector Wheels. What a find! These nifty wheels used to be standard tools in a printer’s shop.

A quick check on the web revealed that these color selector wheels are still being sold today. How are these different from a regular color wheel? These process color selector wheels allow the user to choose or check a CMYK color value before proofing or printing. Hence these wheels were widely used by printers, graphic designers, color separators, and even ad agencies.

How does it work? A regular color wheel illustrates the relationship between the various colors, but the process color selector wheel actually previews what a color will look like before printing. Four

Here's a quick tip from John Hatcher, recently published in Impressions: We recently found some old promo and marketing materials in our warehouse, and amongst the give-away items, we found a box of Process Color Selector Wheels. What a find! These nifty wheels used to be standard tools in a printer’s shop.

A quick check on the web revealed that these color selector wheels are still being sold today. How are these different from a regular color wheel? These process color selector wheels allow the user to choose or check a CMYK color value before proofing or printing. Hence these wheels were widely used by printers, graphic designers, color separators, and even ad agencies.

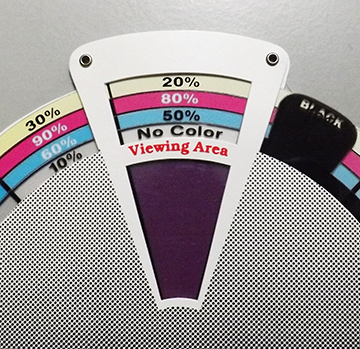

How does it work? A regular color wheel illustrates the relationship between the various colors, but the process color selector wheel actually previews what a color will look like before printing. Four  transparent disks of tinted Cyan, Magenta, Yellow, and Black are mounted on the disk, each printed in 10% increments of color strength, from 0% (clear) to 100% solid color. A viewing window then shows the user what resulting color a particular combination of the four colors will produce.

By moving the various color disks around, one can produce up to 40,000 different color combinations with specified color percentages to arrive at those colors. Pretty cool tool!

John Hatcher served at International Coatings for more than 35 years in various senior managerial positions, including product manager. Prior to working at International Coatings, he owned his own screen printing business.

International Coatings manufactures a complete line of non-phthalate screen printing inks, including a wide variety of whites, specialty inks, special effects inks, color matching systems, additives and reducers. For more information on our products, please visit our website at www.iccink.com.

transparent disks of tinted Cyan, Magenta, Yellow, and Black are mounted on the disk, each printed in 10% increments of color strength, from 0% (clear) to 100% solid color. A viewing window then shows the user what resulting color a particular combination of the four colors will produce.

By moving the various color disks around, one can produce up to 40,000 different color combinations with specified color percentages to arrive at those colors. Pretty cool tool!

John Hatcher served at International Coatings for more than 35 years in various senior managerial positions, including product manager. Prior to working at International Coatings, he owned his own screen printing business.

International Coatings manufactures a complete line of non-phthalate screen printing inks, including a wide variety of whites, specialty inks, special effects inks, color matching systems, additives and reducers. For more information on our products, please visit our website at www.iccink.com.