Using Puff Ink

October 24, 2013

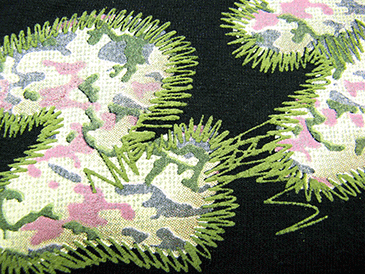

Puff ink, which has been around since the early 1970s, is making a comeback. Considered one of the original “special effects” inks, puff expands during the curing/heating process, adding a 3-D texture to prints.

Even today, printers add puff ink (such as International Coatings' 220 Puff Additive) into their designs as a quick go-to special effect to add dimension and interest into their designs.

Here are a couple of tips from Kieth Stevens for using puff ink as recently published in Impressions:

• By using a thicker stencil, such as a capillary film, to print the puff design, you can achieve a higher loft without having to print-flash-print too many times. This cuts down on production time and - if you are using a manual - cuts down on muscle strain.

• When printing a larger design with puff, creating a fat or coarse half-tone design — rather than one big area — will allow the ink to expand without distorting the overall design. When too much puff ink is printed as a large area, the expanding ink tends to cross over the original borders of the design.

Kieth Stevens is the Western regional sales manager for International Coatings. He has been teaching screen printing for more than 10 years and is a regular contributor to International Coatings' blogs. For more information, visit iccink.com - See more at: http://impressions.issshows.com/screen-printing-news/Screen-Printing-Tip--6922.shtml#sthash.fQgXk234.dpuf

Puff ink, which has been around since the early 1970s, is making a comeback. Considered one of the original “special effects” inks, puff expands during the curing/heating process, adding a 3-D texture to prints.

Even today, printers add puff ink (such as International Coatings' 220 Puff Additive) into their designs as a quick go-to special effect to add dimension and interest into their designs.

Here are a couple of tips from Kieth Stevens for using puff ink as recently published in Impressions:

• By using a thicker stencil, such as a capillary film, to print the puff design, you can achieve a higher loft without having to print-flash-print too many times. This cuts down on production time and - if you are using a manual - cuts down on muscle strain.

• When printing a larger design with puff, creating a fat or coarse half-tone design — rather than one big area — will allow the ink to expand without distorting the overall design. When too much puff ink is printed as a large area, the expanding ink tends to cross over the original borders of the design.

Kieth Stevens is the Western regional sales manager for International Coatings. He has been teaching screen printing for more than 10 years and is a regular contributor to International Coatings' blogs. For more information, visit iccink.com - See more at: http://impressions.issshows.com/screen-printing-news/Screen-Printing-Tip--6922.shtml#sthash.fQgXk234.dpuf