Understanding Off-Contact

May 21, 2014

Here's a new printing tip recently published on Impressions: There is some confusion among screen printers regarding the purpose that off-contact serves in the printing process.

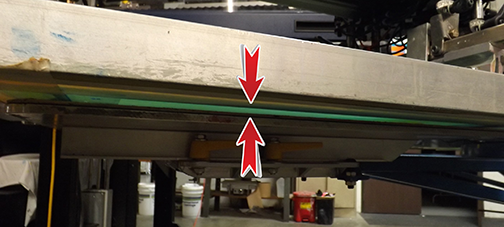

Basically, off-contact is placing the screen a little bit above the platen so that it only contacts the shirt at the point where the squeegee passes over. When the off-contact is correct, the mesh will snap off the shirt, ensuring a clean, smooth and even print.

There are several points to consider when adjusting the screen for optimal off-contact: The necessary amount of off contact is dependent upon several factors, such as:

1) The tension of the mesh: In general, the tighter the mesh, the less you need to worry about the other factors. Having a screen with high tension enables the screen to have minimum off contact. It also maximizes the open area of the screen mesh to allow the ink to flow better.

2) The size of the print: If you are printing a large area of ink then the ink will have a tendency to want to hold onto the mesh and keep it in contact with the garment so you will find that the required off contact will be higher than that for a small print.

3) The amount of ink being laid down: The more ink is being laid down, the more the off-contact needs to be as the thicker deposit of ink will want to hold on to the mesh.

4) The viscosity of the ink: If your ink is high in viscosity for example, it tends to hold onto the screen and not release from the mesh. So keeping the tension of the screen high and thus the mesh opening as open as it can be, allows the required off-contact to be minimized.

Be sure that your pallets are level so that the effect of your off-contact is maximized. Adjusting your off-contact correctly will greatly improve the overall quality of your print.

Kieth Stevens is the Western regional sales manager for International Coatings. He has been teaching screen printing for more than 10 years and is a regular contributor to International Coatings’ blogs. For more ink tips and information, visit iccink.com.

International Coatings manufactures a complete line of phthalate-compliant screen printing inks, including a wide variety of whites, specialty inks, special effects inks, color matching systems, additives and reducers. For more information on our products, please visit our website at www.iccink.com.

Here's a new printing tip recently published on Impressions: There is some confusion among screen printers regarding the purpose that off-contact serves in the printing process.

Basically, off-contact is placing the screen a little bit above the platen so that it only contacts the shirt at the point where the squeegee passes over. When the off-contact is correct, the mesh will snap off the shirt, ensuring a clean, smooth and even print.

There are several points to consider when adjusting the screen for optimal off-contact: The necessary amount of off contact is dependent upon several factors, such as:

1) The tension of the mesh: In general, the tighter the mesh, the less you need to worry about the other factors. Having a screen with high tension enables the screen to have minimum off contact. It also maximizes the open area of the screen mesh to allow the ink to flow better.

2) The size of the print: If you are printing a large area of ink then the ink will have a tendency to want to hold onto the mesh and keep it in contact with the garment so you will find that the required off contact will be higher than that for a small print.

3) The amount of ink being laid down: The more ink is being laid down, the more the off-contact needs to be as the thicker deposit of ink will want to hold on to the mesh.

4) The viscosity of the ink: If your ink is high in viscosity for example, it tends to hold onto the screen and not release from the mesh. So keeping the tension of the screen high and thus the mesh opening as open as it can be, allows the required off-contact to be minimized.

Be sure that your pallets are level so that the effect of your off-contact is maximized. Adjusting your off-contact correctly will greatly improve the overall quality of your print.

Kieth Stevens is the Western regional sales manager for International Coatings. He has been teaching screen printing for more than 10 years and is a regular contributor to International Coatings’ blogs. For more ink tips and information, visit iccink.com.

International Coatings manufactures a complete line of phthalate-compliant screen printing inks, including a wide variety of whites, specialty inks, special effects inks, color matching systems, additives and reducers. For more information on our products, please visit our website at www.iccink.com.