Tips for Achieving Soft Prints with Plastisol Inks

May 03, 2016

Got a client who is asking for soft-hand prints? Here are some tips from Mark Brouillard, recently published in Printwear, on achieving that “barely there” feel that is all the rage in the marketplace, using conventional plastisol inks:

Got a client who is asking for soft-hand prints? Here are some tips from Mark Brouillard, recently published in Printwear, on achieving that “barely there” feel that is all the rage in the marketplace, using conventional plastisol inks:

Additives and Reducers:

One of the simplest ways to achieve a soft-hand feel is to add a soft-hand additive or a reducer (3818 Sentri Curable Reducer) to an existing ink. Either of these products will work well. The reducer is a more concentrated product, so less needs to be added to the ink, but be sure to use a curable reducer if choosing to go that route.

Soft-Hand Base:

Another way to achieve a soft-hand feel is to use a soft-hand base (720 Soft-Hand Base). Using a base can be an economic way to go if you are planning on printing a large quantity of garments. Just beware that tinting the base requires color concentrates rather than ready-to-print inks for increased color strength.

Halftones:

Try using halftones in the artwork as another way to achieve a soft hand, as the halftone dots create open space, thus lessening the ink deposited onto the garment. To maximize this technique, be sure to engineer the artwork with the soft-hand result in mind. This is done by incorporating the substrate color as part of the design whenever possible. For example, if printing on a black T-shirt, use the black of the shirt as a color if the design calls for a “black” color. A note of caution: Halftones can make a print feel a little rough due to the pattern created by the halftones, so using a higher mesh will minimize the rough feel.

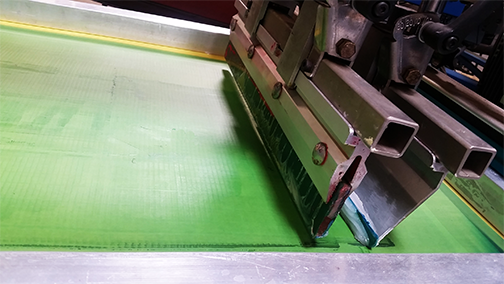

Mat-down Screen:

Many printers use what is often called a mat-down screen to achieve a soft-hand feel on their finished garment. Here’s how it works: Coat a 160 (or higher) mesh screen with emulsion. Be sure the emulsion is smooth and the tension of the screen is very tight.

After exposing the screen (devoid of any image), add the blank screen after the initial flash of the white underbase but before the next color. Using a hard squeegee, add a dab of grease to the screen. Yes, I did say “grease.” The type I’m talking about is an all-purpose lubricant readily sold in stores and online. The grease is used just to lubricate the screen so that the squeegee moves easily across the screen. The mat-down printing must be done quickly after the flash while the white is still in a gel state to get the best effect. Do not over-flash the white underbase as this will otherwise increase the hardness of the ink.

Adding the mat-down screen mats the fabric fibers down and can give the print an incredibly soft hand as well. If you have never done this technique, be sure to practice the timing of the flash and mat-down screen printing. If not timed correctly, the ink can stick—either when it’s under- or over-cured.

Heat Press:

This last tip on how to achieve a soft-hand feel does require extra equipment and labor, but some printers swear by it and many customers love the results. Use a heat press set at medium pressure and a slightly higher temperature than what plastisol inks cure at, which is typically between 325 degrees F and 330 degrees F. Position the garment onto the transfer platen with the print facing up. Then take a Teflon sheet, either glossy or matte—whichever finish is preferred, and place it on top of the print. Heat press the garment for about 2–3 seconds.

Keep in mind that on lighter garments, a soft-hand is easier to achieve than on darker garments, simply because of the pigment load required to mask the dark substrate. The higher the pigment load (more opacity) required to mask the dark substrate, the more ink needs to be deposited, thus the heavier the hand.

And one last tip: the tighter the mesh and the higher the mesh count used for the print, the less ink is deposited. This will help achieve that soft-hand feel.

Mark Brouillard, International Coatings’ product manager, has considerable experience in formulating and manufacturing industrial compounds. For the past 16 years, his focus has been on the formulation and product development of textile screen printing inks. Brouillard coordinates the company’s product development efforts and deployments. For more information, visit iccink.com and read the company’s blog at internationalcoatingsblog.com.

International Coatings manufactures a complete line of non-phthalate screen printing inks, including a wide variety of whites, specialty inks, special effects inks, color matching systems, additives and reducers. For more information on our products, please visit our website at www.iccink.com