TAKING STOCK - Article in Specialist Printing Magazine

November 28, 2020

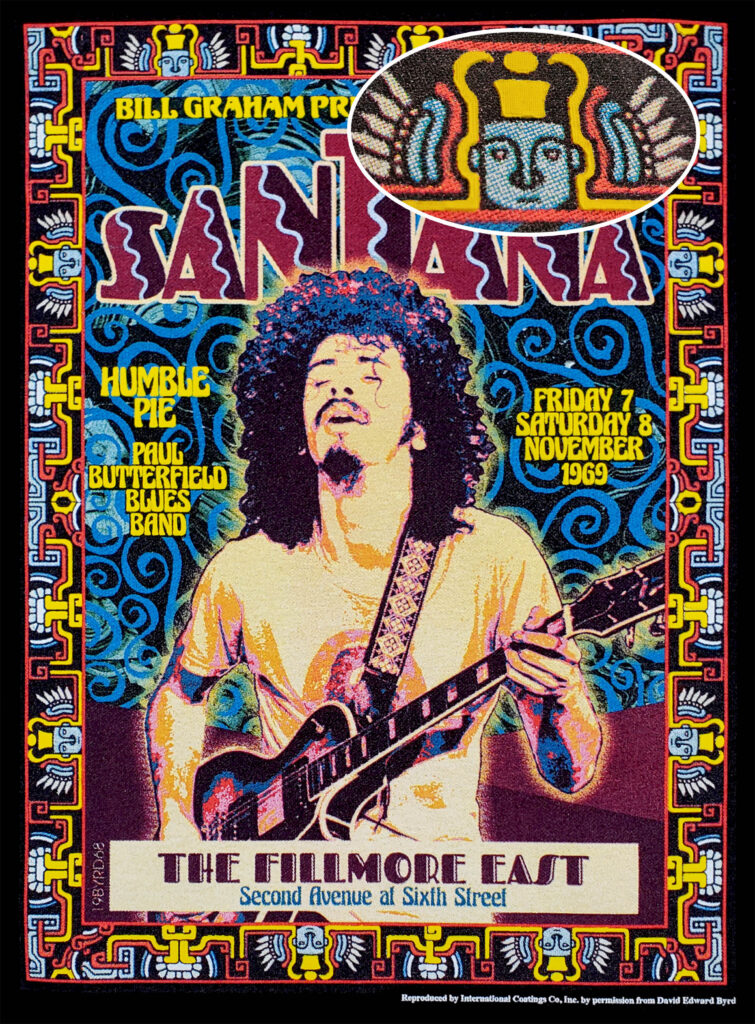

In the midst of a pandemic, now is the time to focus on production processes. In a recent article published in Specialist Printing, Kieth Stevens delves into some of the best ways to safeguard and future-proof your business

During the recent ‘stay at home’ mandate due to the Covid-19 pandemic, I had a chance to do many repairs at my house. Things that had been left un-done for far too long: The leaky faucet, the clogged rain gutter, cleaning the fish pond, endless yard work… on and on. Then I started to think, what if I sell this house and move? Would the new occupant know about all the quirks that come with maintaining this particular house? Such as the sticky window that needs to be lubricated every summer due to the heat... etc. I wouldn’t have to do these chores any longer, but undoubtedly, I would inherit someone else’s headaches at the new house.

Now imagine your screen print company or any other type of company. Imagine all the little daily details it takes to keep things running efficiently and smoothly. The air compressor filters and fluids, light bulbs (type and sizes), drains, sticky roll up doors – who remembers all that stuff? How about the way certain customers like their garments printed, or which ink works best for a pesky team shirt material?

Enter the Covid-19 pandemic: Your shop is forced to downsize, people are let go or sent to work from home – what are you going to do? What if the compressor is acting up again and the person you have been counting on to maintain that is out? Who will you call?

DOCUMENT PROCESSES

A number of years ago, International Coatings went through an ISO (International Organisation for Standardisation) certification process. One of the things about going through the ISO certification is to force a company to look hard at its processes, the way it does things. After successfully operating for over 50 years at the time, there were definite hurdles to getting everyone on the same page. Some have worked at the company for more than 40 years, and they do things “because that’s the way we’ve always done it.” Our consultant called it ‘Tribal Knowledge.’ He posed the important ‘what if’ questions that each shop should consider: What if a staff member is no longer there? Will others know how to take over their function?

There is no time like the present to take a few moment each week or month to try to get all the procedures documented and capture that tribal knowledge. Meet with each head of department and try to capture all the things that they do and know (you can’t fix what you don’t know). When meeting with your key employees, ask what other tasks they do that may not be written down or part of their job description, but that they may do instinctively (they may not think twice about doing this task, but it could be very important or taken for granted).

PROCUREMENT

I have worked at some companies that had employees who had been there for decades, and they do things that no one really thinks about until they go on a well-deserved vacation. All of a sudden, a sinking feeling or panic may pass over you: who unlocks and locks the door on time every day? Where do we purchase those shirts that a particular customer likes? What underbase ink was used on that bleeding performance shirt that the customer just re-ordered?

If you haven’t done so already, create a list of preferred vendors and be sure to find secondary vendors for fast-moving merchandise. That way, you won’t be left in the lurch if one vendor does not have a particular garment in stock that your customer absolutely needs… tomorrow! Take a look at your buying habits and see if there are ways to purchase more effectively. Buy the items you need most in bulk, and resist bulk-buying items that are rarely used.

Don’t forget to reach out to your supply vendors for new and/or better products. Sometimes we can get caught settling into a groove and are content but trust me, it’s worth exploring newer or better options if they make your production function better and with less waste.

CROSS-TRAIN PERSONNEL

Cross-train personnel so each can perform multiple tasks as backup in case one is out sick or no longer with the company. Crosstraining builds the skills of everyone in the company, which is a win-win for you and your employees. Employees can share their knowledge and ideas to improve processes, which can increase motivation and increase employee retention. It may also help curb less desirable employee behaviours such as disrespect and superiority over others. If an employee is reluctant to assist in cross training others, it may be an indication that they do not have the company’s best interests at heart.

STREAMLINE PRODUCTION

While you’re looking around to find ways to document important tasks and cross-train personnel, take a look at how you can also improve your production efficiency. You know how you have that table or corner in your house where odds and ends accumulate and you don’t really notice it anymore – the catchall table? But when you visit someone else’s house, you immediately notice the place where they leave their stuff. Sometimes it’s as simple as re-locating that table or equipment or even moving a chair or other obstacle that’s in the way, in order for the printing process to flow better.

How many steps does it take to place a printed shirt onto the dryer, for example? If you have several printing machines but only one dryer, is that dryer centrally located and easily accessible to all the machines? Do you need to invest in an additional dryer in order to churn out production at a faster rate?

SCREEN DEPARTMENT

The two most overlooked departments at shops I’ve visited are the screen and ink departments. Screen and ink quality are not just important, they are the cornerstones of a print shop! Having the tight meshes on screens, using the correct mesh count and emulsion thickness (emulsion over mesh – EOM) and printing with the right ink for your substrate can streamline your production process and save you a lot of time and money. Running a business is all about the bottom line, and screen and ink quality are minor investments that can lead to big returns.

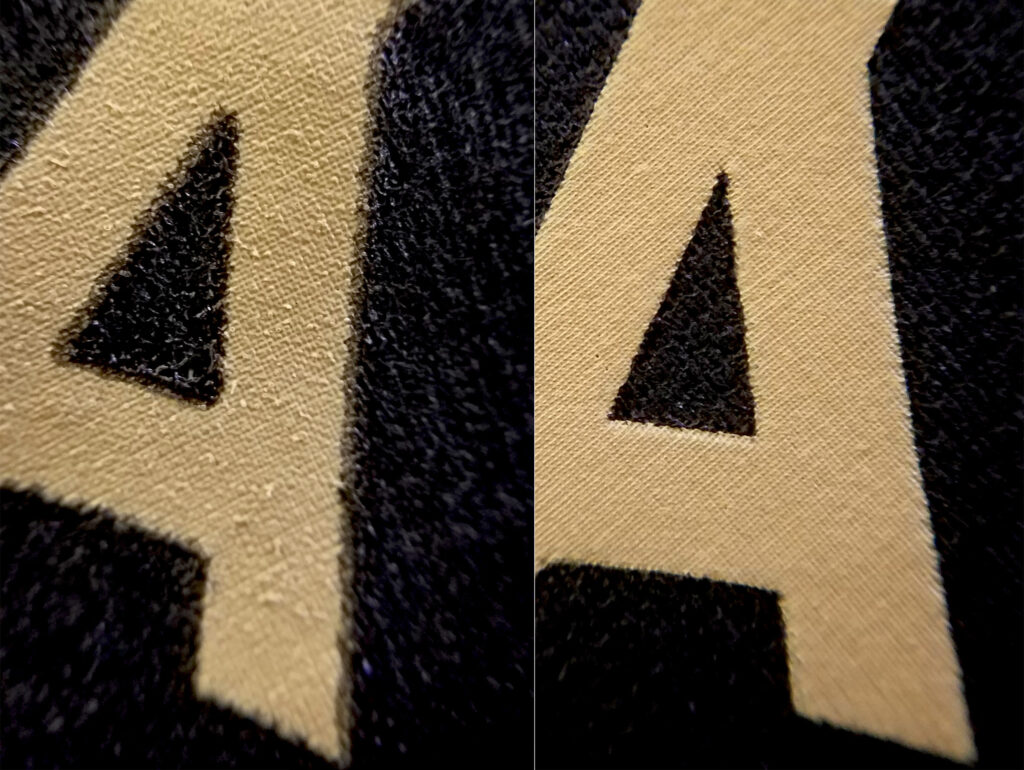

When I visit shops, I often check their screens for emulsion thickness and screen tension, and I often find shops where their screens exhibit many pinholes. Pinholes are created during screen development and are often caused by some form of debris. The debris can be on the screens before coating, deposited on the coated screens, on the exposure unit glass, or even on the film itself. Minimising contact with debris is key to minimising pin holes.

For example, are you guilty of leaving screens out in the open to dry after reclaiming? I’ve visited shops where screens were being dried in the parking lot off a busy street. It may be a good time to take a look at purchasing a drying cabinet instead of leaving the screens out in the open, collecting dust. A drying cabinet will not only dry the screens very quickly, it will also keep them much cleaner.

Check your exposure glass, both on top where you place the screen or underneath on the exposure lamp side. You may find an accumulation of coating or a haze on the exposure lamp side of the glass. This haze, if left to build up, may alter your exposure time and cause under-exposed emulsion. Along with the haze, there might be larger dust particles that can also cause pinholes. Make sure you have a spare exposure lamp handy at all times; most of the time you will not be able to find them at the local hardware store and will lose a day or even more trying to find them. Extremely costly!

Obviously, you should make sure your films are kept clean; however – and we’re also guilty of this on occasion – some shops leave films out on a table for a few days or more and we all know that textile screen printing shops accumulate a lot of debris. Printing hundreds or even tens of thousands of shirts per day creates a ton of lint and/or fibres that are simply not ideal for a photographic process like exposing screens.

INK ROOM

Apply that same focus to your ink room and take a hard look. The ink department is a vital, yet sometimes underappreciated portion of the textile screen printing world. I seldom find a really well-run ink room unless it’s a really large shop that can afford cleaning crews. And because they are so large, they simply can’t afford to waste precious time on press. Keeping the ink room clean will avoid down time and production hick-ups.

One ink room issue that may affect your production is dirty ink in the screen, due to inks being stored without a bucket cover, thus collecting dust and lint. Ink buckets that have ink running down the sides should be wiped clean immediately lest it contaminates a printed garment. Someone could touch the bucket and accidentally transfer the ink, or if the bucket was placed on a table that shirts are later placed on, it may inadvertently soil some shirts. Make sure all the ink containers are covered and that there is nothing inside of them other than clean ink. Don’t leave a wooden paint stick or anything else that can absorb the oils out of the clean ink.

Ink that has been used on a long production run and/or has been exposed to excessive heat (possibly from flashing) should never be returned back into its original container to be reused. Typically, the ink is very thick and may look like cottage cheese. It has done its job and needs to be ‘retired.’ Make sure that the ink containers leaving the ink department are clean going out and are returned to the ink department clean, out of respect for everyone.

If at all possible, limit the customer’s colour choices to a stock colour pallet or at least to standard Pantone colours. Dissuade them from tweaking and creating a custom colour, since you will probably mix too much of it and end up with part of your profits locked up in a container on the shelf, hoping for the customer to return some day. Keep a log of inks mixed, what job the inks were used for and what the formulas are. This will enhance your job repeatability and accuracy. If your ink room employee doesn’t log all the information, you are creating a huge weak link in your company’s future. God forbid that your main ink person goes on vacation or is unreachable – what will you do? Everything should be documented. Most ink manufacturers, including International Coatings, can provide you with an online software that will help you keep track of all your standard or custom formulas.

Take it from me: ‘Ink Doesn’t Think.’ It will do or look pretty much exactly what you tell it to do. You can make it any colour in the rainbow and make it appear shiny, matte, puffy or flat, soft or hard. The beauty is that the ink is usually the most consistent part of the equation but is blamed for 90% of the problems. There are almost countless other variables that can affect the end product, other than the ink. This is not to the say the ink choice can’t be a factor, but many companies simply may not have a full grasp of all the other variables.

QUALITY CONTROL

At the end of each dryer, once your printed shirts are cured, consider keeping a log of not only how many shirts and the various sizes that were printed, but of all the misprints as well and what the cause was. Over time, you should notice a pattern of 1) what your most popular sizes are and in which proportion your customers order them – helpful when ordering shirt supplies, and 2) why those misprints were created, so that you can properly address the problem and correct it going forward.

Whatever you do, do not neglect your quality. Test, test and test! Don’t forget to washtest your prints – preferably before running a full production run – to make sure that your shirts are fully cured. Read or learn about new techniques or tricks that will help you become more efficient in your manufacturing.

ARTWORK

Artwork is a hugely important part of the printing process. The printed shirt is the last and final step of the many steps it took to get the ink on the shirt, but it all started with the art. The artwork goes through some form of colour separation, then to film, then on to screen exposure and development etc. All the steps involve some small loss in quality, so it’s imperative that you start off with the best original artwork possible. Have the customer approve the art before you output the film; have someone – or better yet, two people – approve the films before they are burned.

Double-check for spelling or other grammatical errors and whether the trademark or copyright logo is showing up in the correct area. If all these prior steps are done well, the application of the inks should be the fun part. But if they are not, it becomes the most frustrating part, not to mention the most costly. Don’t skimp on the important stuff; too many times I have found that when trying to save money, shops can go too far and their choices will cost them more in the end.

THE BOTTOM LINE

Let’s face it, we not only print for fun, but for profit. If we aren’t making a profit, it’s not much fun. Anything your shop can do to ship more billable product out the door is a wise decision, even if it may cost a few dollars more for the investment on the front end. Invest in better quality equipment, better quality emulsion, better quality ink, even better quality personnel. Anything that will keep the press producing more products with the least amount of downtime (i.e. less pinholes, thicker emulsion, tighter screens), should be considered. Think of your production line as analogous to getting the most miles per gallon for your car. Everyone wants to know what the MPG is and how to improve it (such as through properly inflated tyres, a tune up, oil changes, tyre rotation, etc). No brainer, right?