Specialty Printing for Success - Part I

August 06, 2015

An article recently published on Impressions' by Kieth Stevens:

Learn the tools and techniques necessary for printing with specialty inks and boost your shop's profits.

It’s an eye-opening experience to think about how much specialty inks have evolved over the years and how the advances or applications of fringe technologies have helped screen-printing industry veterans get where they are today.

The ’80s saw the popularity of a magical, water-based product called Puff Stuff, and what an effect it was. Now, there are multiple types of puff inks available.

Why should a printer invest in specialty printing? In a word: Profits. Customers prefer shops that can give them new or unique prints. The more diversified your shop, the better poised you are to earn money.

How can your shop differentiate itself from others? There are so many choices today for specialty inks, but it doesn’t have to be overwhelming or complicated. Much can be added to a regular print with a tiny amount of bling, such as metallic gold, silver or even clear shimmer inks. Or how about getting creative with glow-in-the-dark ink, which now is available in multiple colors?

For those who want to delve a bit further, remember to have fun with specialty inks. Don’t be intimidated by the choices. Set aside time to play with the options and experiment with how they print and look.

The artistic aspect of our industry sets it apart from others. I got my start in high school, printing on a litho press, and it just seemed to be too aseptic and cut-and-dry. My vocational teacher, Mr. Jones, was cool and inspirational. He introduced me to screen printing, which seemed much more engaging. It was a process where I could use my imagination and — as I later learned — allowed me to express myself artistically.

Take the aforementioned puff ink. Today, there are several different types, including standard puff, suede puff and a newer type, BlowOut Base. The latter is similar to a “blister puff” — one that has a “skin” and is spongy rather than hard to the touch.

In addition, there now are all kinds of gel inks being used, such as a clear variety that simulates the clarity of looking through a glass window. Others can be tinted and made to resemble a neon bulb or stick of red licorice. Some gels are used as adhesives for caviar beads or other loose particles such as glitter flakes, and even as an on-press foil adhesive.

Did you know you can add a scent to ink that makes printed strawberries smell as if they were just picked? How about a chocolate bar that smells irresistible?

Some of my favorite types of specialty inks are those that can change colors. Some, called hydrochromatic, will change colors when wet. Others, called thermochromatic, change colors when exposed to temperature changes. Another popular one — and my favorite, called orthochromatic or photochromatic — changes color when it is exposed to outdoor light.

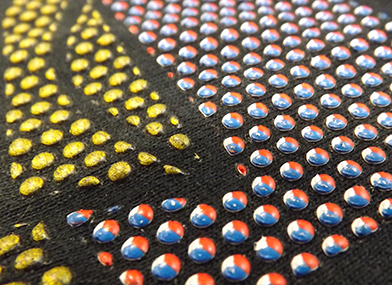

One type of specialty ink that hit our screens in the mid-to-late ’90s is what we now refer to as high-density (HD) ink. This thick ink has some puff added so that when printed through a thick stencil (200-400 microns), it has a sharp edge. It can be stacked and combined with regular plastisol inks to give some very interesting images and dimensions. Many prints that win awards at trade shows contain HD elements.

Kieth Stevens is the Western regional sales manager for International Coatings. He has been teaching screen printing for more than 10 years and is a regular contributor to International Coatings’ blogs. For more information, visit iccink.com and read the company’s blog at internationalcoatingsblog.com.

International Coatings manufactures a complete line of non-phthalate screen printing inks, including a wide variety of whites, specialty inks, special effects inks, color matching systems, additives and reducers. For more information on our products, please visit our website at www.iccink.com.