Ensure Successful Screen Printing with Proper Tools and Safety Part II

November 28, 2012

This week we are featuring Part II of "Ensure Successful Screen Printing with Proper Tools and Safety," part of Kieth Stevens' popular "Top 5" articles published in Impressions. Part II discusses some basics on safety in- and around- the printing zone:

Ensure Successful Screen Printing with Proper Tools and Safety

Safety First

In addition to having the proper tools and supplies handy, shop safety is of utmost importance to successful screen printing. I started printing in my mid teens and in those early days of the screen print industry, safety was not always a top priority in the shops I worked in. As a result, I have had numerous injuries stemming from chemicals, electricity and machines. Here are some of the main categories I consider of high importance to take precautions in order to prevent injuries:

1. Cleanliness and Orderliness: I cannot stress enough how important something so obvious is to the screen print process. Besides it impacting your overall bottom line (for example, by keeping individual ink colors from being contaminated), it also may prevent injuries. Be sure to have designated places for all your inks, equipments and tools. This will help you spend less time locating missing tools or equipment, avoid tripping over misplaced buckets, and avoid cuts stemming from misplaced razor blades or knifes.

2. Chemical Safety Precautions: During the screen printing process, there are many chemicals that are used in and around the print process. Many are solvents used to clean screens, spills and equipment while others are mixed into the ink to thin or thicken the viscosity. Since chemicals can be inhaled or absorbed through the skin, be sure to use any solvents in well-vented areas only and use gloves where necessary.

I have burned my skin using Zylene/MEK solutions and even using UV inks, so it is a good idea to use preventative measures that protect your eyes, skin and nose (to prevent inhalation) whenever handling chemicals. Be sure to read the labels of any chemicals to determine what safety precautions need to be taken. A product’s MSDS (Material Safety Data Sheet) also lists first aid measures and more safety instructions.

Let me give you an extreme example: A can of spray adhesive accidentally ended up inside a dryer at a shop I was working in. The temperature in the dryer heated up the can and the highly pressurized contents, resulting in an explosion that set the dryer on fire. Luckily, no one got hurt but the dryer was damaged and production had to be stopped for a time.

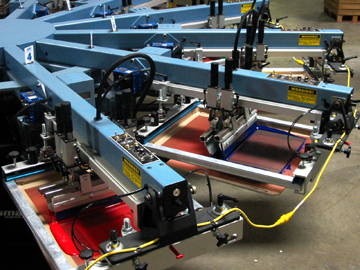

3. Equipment Safety Training: If a shop has any electronic equipment — be it a flash, a dryer, or an automatic printing machine — every staff member needs to be trained on how to safely use it. Be sure that the machines also have the necessary safety guards or covers in place so that the engine parts are not exposed. I speak from experience here, as I have gotten my foot stuck in the chain drive of a dryer that didn’t have a cover over the engine part and have had my hand smashed by an automatic machine.

4. Electrical Safety Precautions: When dealing with electricity, take extra precautions such as installing a lock out box over the electrical controls. This way, if repairs are needed, the repairing mechanic can shut off the electricity, lock the box and not have anyone else turn it on accidentally while repairs are in progress. If this safety precaution is not possible, let everyone in the plant know when repairs are being made so that no one accidentally turns on the electricity. Whenever possible, schedule repairs after hours when the work crew has left.

Again, I am mentioning this because I have been shocked several times while fixing wiring on lights or wiring a plug and someone turned on the electricity, not knowing that I was working on the repairs.

5. Stay Alert: Many accidents happen in the workplace due to lack of alertness or common sense. To help combat tiredness or drowsiness, take breaks and keep hydrated. Moving or walking around also will help energize the mind and body. Also, keep distractions to a minimum when working in a high-paced environment, especially around automated equipment. Whether the distraction comes in the form of music, cell phones, computers or interaction with other coworkers, minimize distractions to focus on the tasks at hand.

Use common sense in avoiding accidents and injuries. While this is easily said, I know I’ve done some stupid things. Once, I asked a co-worker to throw a can of spray to me while I was standing on the other side of an automatic machine. I’m usually a good catcher, but this time I failed to catch the can and it struck my forehead instead. I still have the scar to show for it.

While this list is not exhaustive in preventing or avoiding accidents or injuries, I hope that some of these safety tips will help minimize some safety pit-falls at your shop.

Kieth Stevens is the Western regional sales manager for International Coatings. He has been teaching screen printing for more than 10 years and is a regular contributor to International Coatings’ blogs. For more information, visit iccink.com and read the company’s blog at internationalcoatingsblog.com.

International Coatings manufactures a complete line of phthalate-compliant screen printing inks, including a wide variety of whites, specialty inks, special effects inks, color matching systems, additives and reducers. For more information on our products, please visit our website at www.iccink.com.

This week we are featuring Part II of "Ensure Successful Screen Printing with Proper Tools and Safety," part of Kieth Stevens' popular "Top 5" articles published in Impressions. Part II discusses some basics on safety in- and around- the printing zone:

Ensure Successful Screen Printing with Proper Tools and Safety

Safety First

In addition to having the proper tools and supplies handy, shop safety is of utmost importance to successful screen printing. I started printing in my mid teens and in those early days of the screen print industry, safety was not always a top priority in the shops I worked in. As a result, I have had numerous injuries stemming from chemicals, electricity and machines. Here are some of the main categories I consider of high importance to take precautions in order to prevent injuries:

1. Cleanliness and Orderliness: I cannot stress enough how important something so obvious is to the screen print process. Besides it impacting your overall bottom line (for example, by keeping individual ink colors from being contaminated), it also may prevent injuries. Be sure to have designated places for all your inks, equipments and tools. This will help you spend less time locating missing tools or equipment, avoid tripping over misplaced buckets, and avoid cuts stemming from misplaced razor blades or knifes.

2. Chemical Safety Precautions: During the screen printing process, there are many chemicals that are used in and around the print process. Many are solvents used to clean screens, spills and equipment while others are mixed into the ink to thin or thicken the viscosity. Since chemicals can be inhaled or absorbed through the skin, be sure to use any solvents in well-vented areas only and use gloves where necessary.

I have burned my skin using Zylene/MEK solutions and even using UV inks, so it is a good idea to use preventative measures that protect your eyes, skin and nose (to prevent inhalation) whenever handling chemicals. Be sure to read the labels of any chemicals to determine what safety precautions need to be taken. A product’s MSDS (Material Safety Data Sheet) also lists first aid measures and more safety instructions.

Let me give you an extreme example: A can of spray adhesive accidentally ended up inside a dryer at a shop I was working in. The temperature in the dryer heated up the can and the highly pressurized contents, resulting in an explosion that set the dryer on fire. Luckily, no one got hurt but the dryer was damaged and production had to be stopped for a time.

3. Equipment Safety Training: If a shop has any electronic equipment — be it a flash, a dryer, or an automatic printing machine — every staff member needs to be trained on how to safely use it. Be sure that the machines also have the necessary safety guards or covers in place so that the engine parts are not exposed. I speak from experience here, as I have gotten my foot stuck in the chain drive of a dryer that didn’t have a cover over the engine part and have had my hand smashed by an automatic machine.

4. Electrical Safety Precautions: When dealing with electricity, take extra precautions such as installing a lock out box over the electrical controls. This way, if repairs are needed, the repairing mechanic can shut off the electricity, lock the box and not have anyone else turn it on accidentally while repairs are in progress. If this safety precaution is not possible, let everyone in the plant know when repairs are being made so that no one accidentally turns on the electricity. Whenever possible, schedule repairs after hours when the work crew has left.

Again, I am mentioning this because I have been shocked several times while fixing wiring on lights or wiring a plug and someone turned on the electricity, not knowing that I was working on the repairs.

5. Stay Alert: Many accidents happen in the workplace due to lack of alertness or common sense. To help combat tiredness or drowsiness, take breaks and keep hydrated. Moving or walking around also will help energize the mind and body. Also, keep distractions to a minimum when working in a high-paced environment, especially around automated equipment. Whether the distraction comes in the form of music, cell phones, computers or interaction with other coworkers, minimize distractions to focus on the tasks at hand.

Use common sense in avoiding accidents and injuries. While this is easily said, I know I’ve done some stupid things. Once, I asked a co-worker to throw a can of spray to me while I was standing on the other side of an automatic machine. I’m usually a good catcher, but this time I failed to catch the can and it struck my forehead instead. I still have the scar to show for it.

While this list is not exhaustive in preventing or avoiding accidents or injuries, I hope that some of these safety tips will help minimize some safety pit-falls at your shop.

Kieth Stevens is the Western regional sales manager for International Coatings. He has been teaching screen printing for more than 10 years and is a regular contributor to International Coatings’ blogs. For more information, visit iccink.com and read the company’s blog at internationalcoatingsblog.com.

International Coatings manufactures a complete line of phthalate-compliant screen printing inks, including a wide variety of whites, specialty inks, special effects inks, color matching systems, additives and reducers. For more information on our products, please visit our website at www.iccink.com.

International Coatings: The Intelligent Choice

International Coatings: The Intelligent Choice