Creating Pantone Formulas Part 1

March 15, 2018

How Do You Create A Pantone® Color Formula? A Behind-the-Scenes Look

How Do You Create A Pantone® Color Formula? A Behind-the-Scenes Look

This article was published in Impressions Magazine.

How do we develop the most exact Pantone® color matching formulations? The short answer is that it’s not as easy as it seems and a lot of effort is involved in getting it done.

Most printers already know that Pantone® is the main color standard key used worldwide. The system consists of color catalogs containing different shades of various colors. Each color shade is identified with a unique number, often referred to as the "Pantone®" or "PMS" color. Having such a standard makes it easy to reference a color exactly and eliminates mistakes or misunderstandings. A customer’s “lavender blue” may not correspond to a printer’s idea of “lavender blue,” but when both are referencing Pantone®7451C, the chance that the printer’s color choice matches the customer’s color vision, increases.

Colors may also look different printed on different types of substrates, so the Pantone® color catalogs are separated into coated (C), uncoated (U) and matte (M) guides to give the user as much accuracy as possible. Most printers use the coated or uncoated values, often to simulate either shiny plastisol (coated) or matte water-base inks (uncoated).

Another important point to note is to never match a color against a color swatch online. Each monitor is different and a color image viewed on one monitor will be vastly different when viewed on another monitor. Be sure to invest in an actual Pantone® catalog instead.

It’s not uncommon for customers to request their designs be printed in specific colors. For example, some customers ask for their logo or art to be matched to specific Pantone® colors. Rather than trying to mix and match the ink colors on their own, printers have the option of using a color matching system.

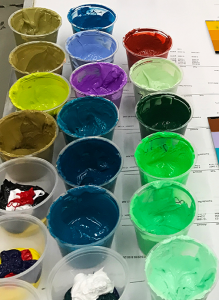

International Coatings offers a number of color matching systems in its UltraMix® line, most notably the 7500 Series Color Mixing System. These systems consist of a number of ‘primary’ colors that when mixed according to a formula, will produce a fairly close Pantone® color simulation. The formulas for the various color mixing systems we carry are published on our Formulation Calculator website (http://www.iccultramix.com). Obviously, these formulas are specific to our color systems and would not match if other ink systems were used.

International Coatings offers a number of color matching systems in its UltraMix® line, most notably the 7500 Series Color Mixing System. These systems consist of a number of ‘primary’ colors that when mixed according to a formula, will produce a fairly close Pantone® color simulation. The formulas for the various color mixing systems we carry are published on our Formulation Calculator website (http://www.iccultramix.com). Obviously, these formulas are specific to our color systems and would not match if other ink systems were used.

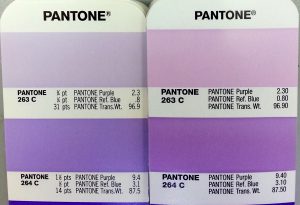

So how are the formulas developed? Well, we start by getting a new Pantone® book every year and then meticulously go through every color, one-by-one. Considering there are over 1,867 existing colors, it’s a monumental task. To complicate things, Pantone® releases over 100 new colors around March of each year! For example in 2016 alone, Pantone® added 112 new colors.

Aside from the number of colors that we need to match and manage, we also watch for color shifts in the Pantone® colors. Many don’t realize that colors in the Pantone® booklets tend to shift with age or exposure to harsh lighting or operating conditions. (It’s important to store the books in a protected environment and switch them out on a regular basis.) In addition, Pantone®’s “standard” colors often do not match exactly from year to year. This may be due to their printing process or changes in the paper they print on; but colors from a book printed last year or a couple of years ago, may be different from the book coming out this year. This may be true on only certain shades or colorways, but may present a significant shift nevertheless.

Stay tuned for Part 2 of the article.

Mark Brouillard is International Coatings’ product manager and has considerable experience in formulating and manufacturing industrial compounds. For the past 16 years, his focus has been on the formulation and product development of textile screen printing inks.

International Coatings manufactures a complete line of Centris™ non-Phthalate screen printing inks, including a wide variety of whites, specialty inks, special effects inks,color matching systems, additives and reducers. In addition, International Coatings also manufactures a line of AXEON™ non-Phthalate, non-PVC special effects inks. For more information on our products, please visit our website at www.iccink.com.