Combat Dye Migration

February 22, 2013

Here is a quick tip on how to combat dye migration, published in Printwear by Ed Branigan:

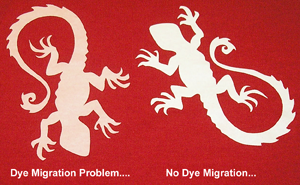

Most screen print practitioners have encountered dye migration or “bleeding” issues when printing on polyester fabrics. Dye migration often doesn’t happen immediately after printing but can develop over several hours, days, or even weeks.

Unfortunately, there is no 100 percent cure or prevention for this problem, especially on all the polyester fabrics that are on the market today. However, there are some good bleed-blocking inks on the market today that can help reduce or stop dye migration.

In addition:

Here is a quick tip on how to combat dye migration, published in Printwear by Ed Branigan:

Most screen print practitioners have encountered dye migration or “bleeding” issues when printing on polyester fabrics. Dye migration often doesn’t happen immediately after printing but can develop over several hours, days, or even weeks.

Unfortunately, there is no 100 percent cure or prevention for this problem, especially on all the polyester fabrics that are on the market today. However, there are some good bleed-blocking inks on the market today that can help reduce or stop dye migration.

In addition:

- Avoid curing the garment at temperatures above the recommended 320ºF level. Heat often activates the dye migration process.

- Use a low-cure additive that lowers the curing temperature of the ink and can help prevent the dye from migrating.

- Always test fabric for dye migration prior to a production run, several days in advance if possible. Print a white or light-colored ink onto the fabric and then check for any dye migration after curing.

International Coatings: The Intelligent Choice

International Coatings: The Intelligent Choice